Are you a pioneering SME, startup in fiber composites, or a leading researcher at an institute? Picture a world where your innovation flourishes, your solutions make an impact, and you’re driving industry change alongside industry leaders. If this resonates with you, then Collab Composite is your platform.

Coming soon

Coming soon!

In the Aeronautical industry the positive effects of composites such as wight benefits and corrosion resistance are starting to show in the latest commercial programs. As composites are moving towards a mainstay solution for larger structural parts, further advantages or possibilities of composites are explored.

One area of great interest to the industry is to functionalize the composites and make it “intelligent”. This could be by adding functionality such as conductivity or by adding monitoring functionality in the materials.

Saab is interested to learn about your technology or solutions that will allow a composite material to overcome the drawbacks compared to metallic materials in specific situations or to monitor itself with regards to loading of functionality.

Coming soon!

Hitachi Energy is facing an unprecedented growth due to several factors such as the decarbonization, electrification and general increased energy consumption. Composite materials are the future to solve the many challenges that Hitachi Energy are facing by offering mechanical strength and electrical insulation with decreased weight.

The electrical insulation is dependent on the mechanical loads on the material. Testing, designing and monitoring/indication mechanical loads are of utter importance, but high voltage components operate in complex environments, specifically at elevated temperatures between ~70°C – 140°C.

Composite materials and methods to test and monitor mechanical loads in complex environments with elevated temperatures. Solutions that either increases mechanical performance or just monitors loads during operations are of interest.

Coming soon!

Coming soon!

Check out the challenges from Saab & Hitachi Energy. Decide which ones are for you.

Apply via F6S and describe which challenges your solution addresses.

SAAB and Hitachi Energy will review the applications and invite the most interesting companies to join a COLLAB workshop.

At the COLLAB workshop, you will present your ideas and discuss potential collaborations with Saab & Hitachi Energy to move into a Proof-of-Concept project

If you need help or have questions, just contact us at collab@abi.se and we will arrange for this.

As as Start-up simply submit your proposed new services or technology (follow our short template) and we will review and present this to our Industry partners.

Industry partners will review your proposal and decide if to invite you to present them. These pitch days will happen 3-4x per year. If invited we help you prepare for this.

Pitch template (PPT)

If there is a match between your ideas and the industry needs you will get the opportunity to agree on a joint proof-of-concept project (typically 3-6 months long). Collab will then support you in performing this.

As a start-up active in the field of fiber composites, we place you in front of world-leading companies to solve industry challenges together. You will get the opportunity to:

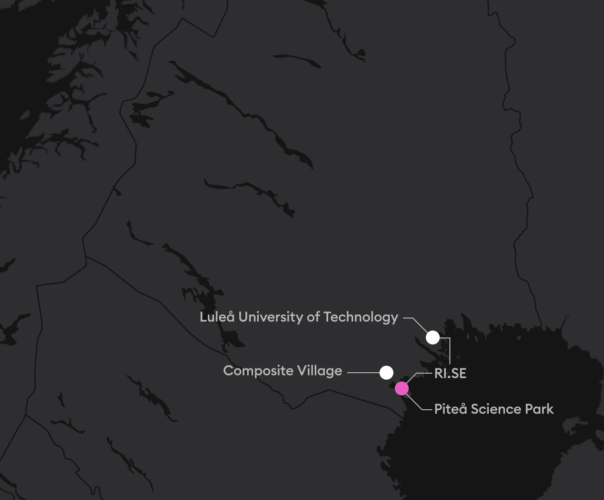

In Öjebyn, outside of Piteå, you will find over 50 years of experience within the development of many different kind of fiber composite products and processes and a close coopeation between companies, the research institute RISE and academia. There are in total vast resources to be found, both competence and equipment.

Collab act as a neutral partner that facilitates the process and cooperation between major industry actors and start-ups. We give you access to resources and facilities to innovate.

Here is a summary of what our expert partner RISE can offer in terms of support in the context of Collab Composite. Read more

You might need additional or supplementary competence during your proof-of-concept project. Via Collab Composite we can hook you up with the expertise in Öjebyn.

RISE and the companies together offer a comprehensive open testbed. The emphasis is on RISE, but the companies equipment is also part of the combined testbed. This means that most processes for manufacturing fiber composites are available in Öjebyn. RISE and the companies can also help out when it comes to produce prototypes or smaller pre-series.

Piteå Science Park offers an environment where you can get an office, find likeminded startups and industries, and get help and support for whatever you and your team will need.

Fiber composite carries the potential to dramatically improve a wide range of applications where traditional composites, metals, and other heavy materials have been dominant. But it must happen now. Collab aims to find innovative applications and usage from renewable and sustainable fiber composites. For example: